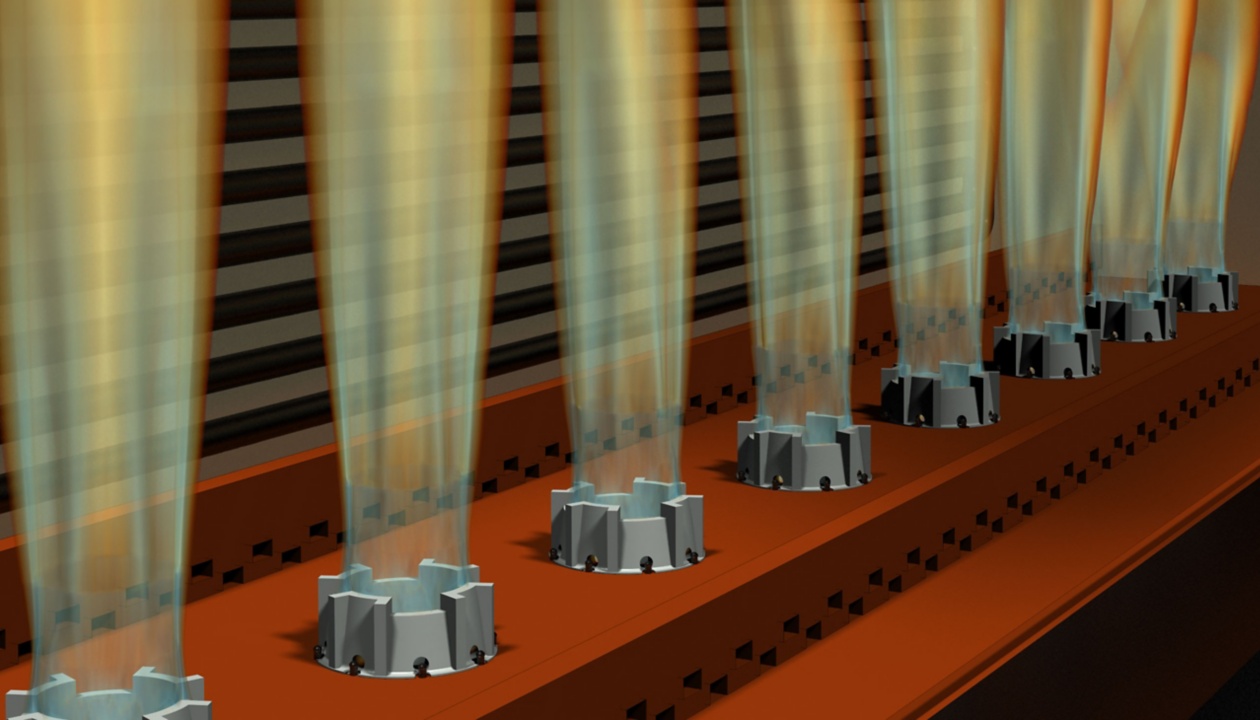

Technologie de combustion élévatrice

En tirant parti de la dynamique des fluides numérique (CFD) avancée, nous pouvons vous aider à optimiser les performances de combustion, à réduire les émissions et à améliorer l’efficacité et la fiabilité du transfert de chaleur dans vos opérations. Notre utilisation de la CFD garantit que vos systèmes répondent aux exigences réglementaires tout en soutenant vos objectifs de durabilité, offrant à la fois performance et tranquillité d’esprit.

Optimiser les performances de combustion

Atteindre des performances de combustion optimales est fondamental pour notre engagement envers l’excellence. À l’aide de simulations très précises, nous affinons les éléments cruciaux du mélange air-carburant, de la stabilité de la flamme et de la distribution de la température. En éliminant les inefficacités et en optimisant les réactions de combustion, nous pouvons vous aider à améliorer l’efficacité opérationnelle et à prolonger la durée de vie de votre équipement.