Boiler Burners

John Zink’s boiler burners deliver ultra-efficient, industry-leading performance, and are designed to meet stringent standards and diverse fuel challenges across various industrial applications.

Ultra-Low NOx Boiler Burners

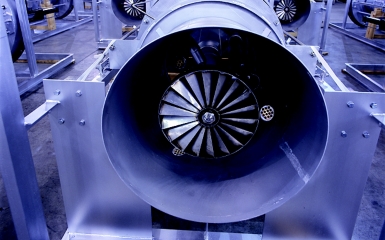

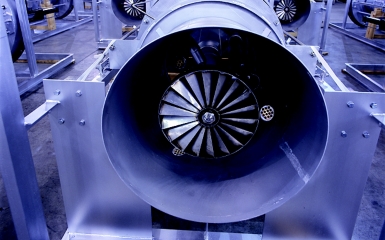

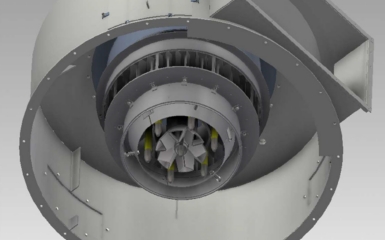

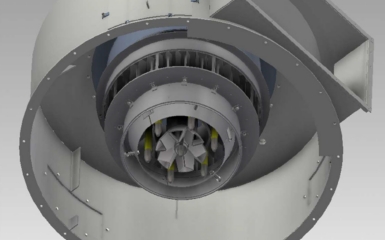

ECOjet® Edge Ultra-Low NOx Burner

ECOjet® Edge Ultra-Low NOx Burner

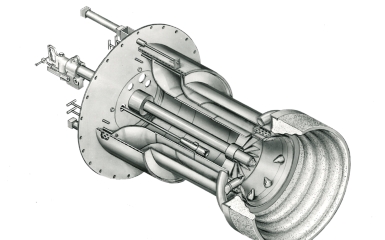

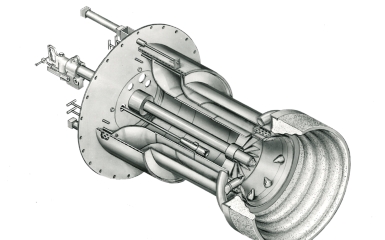

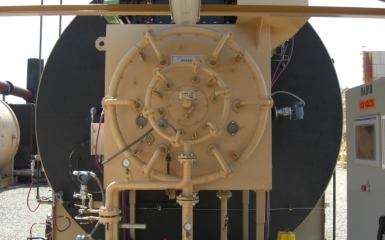

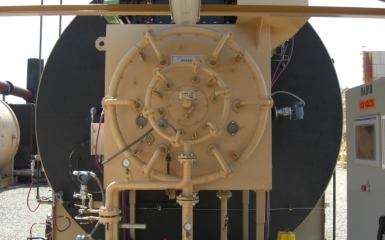

Rapid Mix Burner (RMB™)

Rapid Mix Burner (RMB™)

QLN® Low NOx Burners

QLN® Low NOx Burners

Low NOx Boiler Burners

T-Fired (Tangentially Fired) Burners

T-Fired (Tangentially Fired) Burners

Variflame™

Variflame™

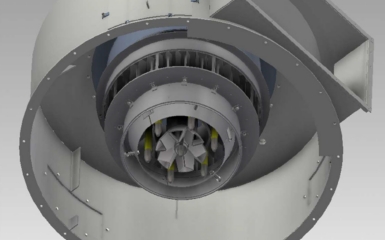

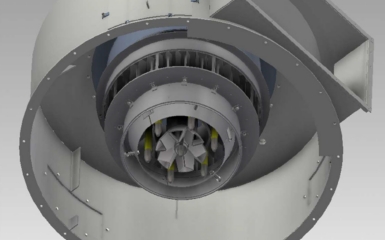

Dynaswirl-LN™ Burner

Dynaswirl-LN™ Burner

Divided Flow (DFL™) Low-Emission Burner

Divided Flow (DFL™) Low-Emission Burner

CPF™ Low NOx Burner

CPF™ Low NOx Burner

Specialty Combustion

John Zink specializes in handling a variety of challenging fuels, ensuring reliable and efficient performance across diverse applications.

Low Btu Fuel / Fuel Complexity

Our Low Calorific Value (LCV) burners are engineered to combust fuels with mass flows that are too large for conventional burners, such as blast furnace gas. These burners allow low-pressure waste and process gases to be utilized for sole or joint power generation. The unique design leverages air velocity to mix LCV gas into the furnace, achieving complete combustion and maintaining low CO levels.

Biomass Fuel

Harnessing the energy of by-products can significantly reduce fossil fuel consumption and alleviate disposal challenges. Our combustion systems are tailored for the agricultural, pulp and paper, forest products, and food processing industries to generate low-cost energy from biomass. This sustainable approach not only minimizes waste but also leverages renewable energy sources.

Hydrogen Fuel

With the growing emphasis on clean energy, hydrogen fuel is becoming increasingly important. Our advanced burner technologies are capable of efficiently burning hydrogen, providing a sustainable solution for power generation. These burners are designed to handle the unique characteristics of hydrogen, ensuring safe and effective combustion.

Recovered Flare Gas

Our burner systems also capitalize on recovered flare gas, transforming what would be wasted energy into a valuable resource. By incorporating this gas into our combustion process, we help industries reduce their carbon footprint and make better use of available resources. These solutions can be custom-engineered to fit specific plant requirements, optimizing both environmental and economic performance.

Biomass Boiler Burner

Biomass Boiler Burner

T-Fired (Tangentially Fired) Burners

T-Fired (Tangentially Fired) Burners

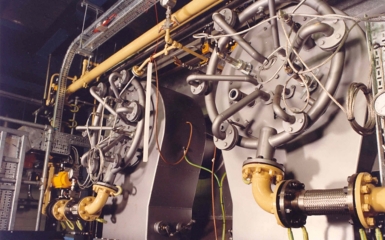

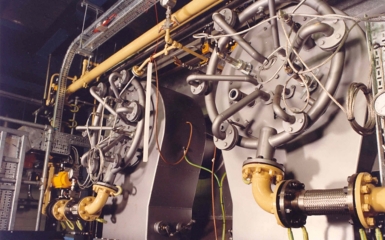

Duct Burners

Duct Burner

Duct Burner

ProLine™ In-Line Duct Burner

ProLine™ In-Line Duct Burner

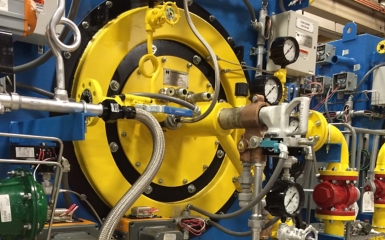

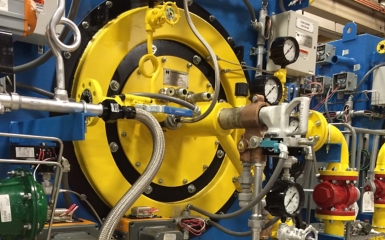

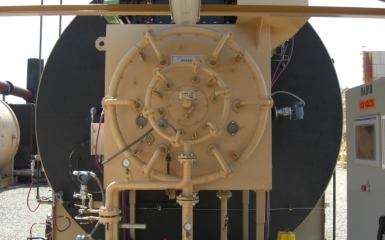

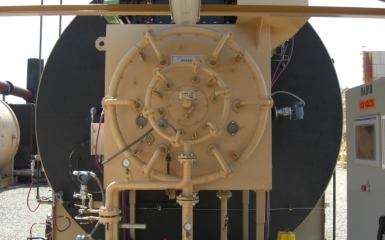

Air Heaters/Process Heaters/ OTSG Burners

John Zink's air heater, process heater and OTSG burner packages are designed to enhance steam generation efficiency and performance. These burners are recognized for their integration with refractory chambers, producing hot exhaust for various industrial applications. They are part of a comprehensive portfolio that includes legacy and current models, supporting aftermarket needs.

ProLine™ In-Line Duct Burner

ProLine™ In-Line Duct Burner

Biomass Boiler Burner

Biomass Boiler Burner

QLN® Low NOx Burners

QLN® Low NOx Burners

Post Combustion

Selective Catalytic Reduction (SCR) Systems

Selective Catalytic Reduction (SCR) Systems

Partner With John Zink

With nearly a century of leadership in combustion and emission control, we are committed to being your trusted partner. Collaborate with John Zink for reliable solutions backed by expert service and support.