Features

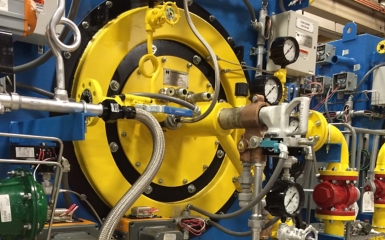

- NOx Reduction: Achieves up to a 50% NOx reduction over conventional burners and up to a 90% NOx reduction with FGR or OFA.

- Low Stack O2 Levels: Operable with stack O2 levels of 0.5% or less.

- Stable Combustion: Minimizes boiler vibration and ensures reliable flame stability with FGR rates as high as 45%.

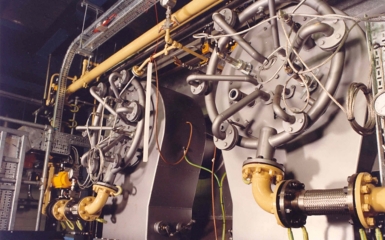

- High Turndown Ratios: Offers ratios of 8:1 on oil and up to 20:1 on gas.

- Low Emissions: Reduces NOx, CO, VOC, and particulate matter (PM) emissions.

- Hydrogen-Ready: Optimized to fire hydrogen and other alternative fuels, supporting future energy transitions.

- Gas/Oil Firing: Capable of firing both fuels simultaneously.

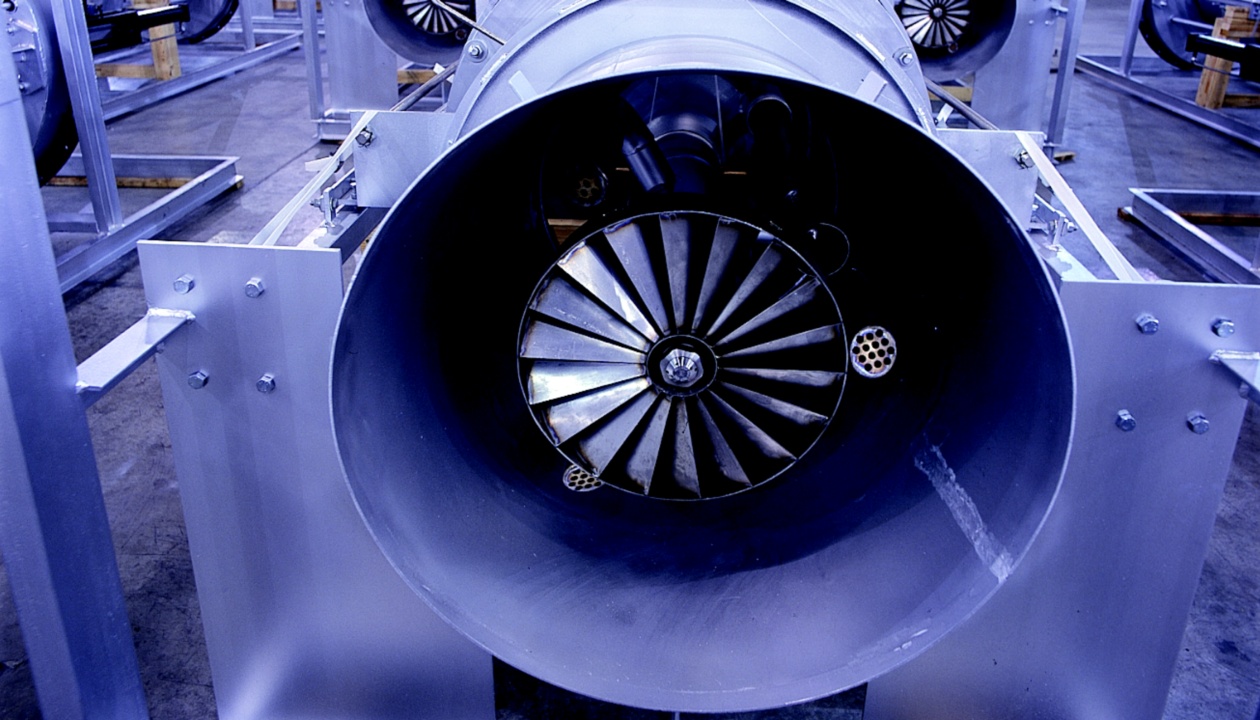

- No Moving Parts: Ensures reliable service with low maintenance.

- Air Sleeve Damper: Allows for taking burners out of service efficiently.

- Optional Removable Gas Injectors: Enhances flexibility and maintenance.