Knowledge Hub

Welcome to the John Zink Knowledge Hub, your go-to resource for combustion and emission control insights and updates. Tailored for industry professionals, this hub delivers a continuous stream of content ranging from deep-dive technical articles and product data sheets to technical articles and updates on the latest environmental regulations affecting combustion systems. This hub keeps you up to date with the information and insights you need.

Knowledge Hub

Filter

Category

Tags

NO RESULTS FOUND

Try refining your search filters or browsing our other content types. We're always adding new content, so please check back soon.

Unlocking Millions in Value with the Correct Burner Tip

Margin that Matters: Exceeding Emissions Standards with ECOjet Edge+

When Reliability Matters Most

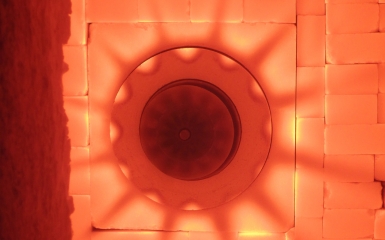

Burner Tile and Why It's Important

Burner tiles are often mistaken for a simple piece of refractory or fire brick, but in reality, they are a critical component of burner performance. The burner tile serves as the heart of the burner, influencing airflow, fuel-air mixing, flame stability, flame shape, and emissions control. If improperly installed or poured incorrectly, burner tiles can significantly impact efficiency, emissions, and overall operation.

How Ambient Weather Conditions Can Affect Burner Performance

Burner performance is influenced by ambient weather conditions, particularly temperature and humidity. Burners function by pulling in a specific volume of air for combustion. Changes in ambient conditions affect oxygen content, air density, and draft, all of which impact combustion efficiency, emissions, and flame stability.

Retrofitting with Ultra-Low NOx Burners

Retrofitting a fired heater with ultra-low NOx burners requires a case-by-case evaluation to determine feasibility and necessary modifications. While some ultra-low NOx burners can be installed in existing burner cut-outs with minimal changes, most retrofits require modifications to heater steel and refractory.

Radiant Wall Burners & Flame Patterns

Radiant wall burners are widely used in ethylene plant cracking heaters, where precise heat distribution is essential for process efficiency. These burners are designed to fire pre-mixed gas, typically in a horizontal position, and are installed in the heater wall to create even heat radiation.

Understanding and Preventing Flame Impingement on Process Tubes

Flame impingement is a critical concern in process heaters, particularly when hydrocarbon feeds are involved. If left unchecked, it can lead to tube overheating, coking, and even catastrophic failure. Explore how to identify flame impingement, its impact on operations, and best practices to prevent and correct the issue.

Jake Tillson, Project Manager

Meet Jake Tillson, project manager in the retrofit group at John Zink. Since joining in 2021, Jake has combined his passion for customer collaboration with his operational expertise to manage complex projects. His journey reflects John Zink’s commitment to growth, innovation, and a culture where employees can thrive.

Devin Call, Project Coordinator

Meet Devin Call, project coordinator for flares and thermal oxidizers at John Zink. Since joining in 2023, Devin has embraced the company’s culture of collaboration, problem-solving, and continuous growth. Whether ensuring smooth project execution or supporting colleagues in their day-to-day challenges, Devin thrives on teamwork and a shared vision for success.

Michelle Torres, Manager - Order Management

Meet Michelle Torres, manager of the order management team at John Zink. Since joining in January 2020, Michelle has been a driving force behind efficient workflows and cross-departmental collaboration, ensuring customer needs are met with precision and care. Passionate about fostering innovation and embracing challenges, she contributes to John Zink’s legacy of excellence while continuously growing both professionally and personally.

Thomas Creekmore, Vapor/Flares Aftermarket Account Manager

Meet Thomas Creekmore, our vapor and flares aftermarket account manager, who has been growing, leading, and building strong relationships at John Zink since 2014. From warehouse operations to sales and leadership, his journey reflects our commitment to excellence and integrity. Get to know Thomas as he shares his career path, favorite traditions, and what makes him proud to be part of the team.

Anne Schonacher, Innovation Manager

Meet Anne Schonacher, a valued member of the John Zink team since 2014. Drawn by John Zink’s culture, she now plays a key role in managing innovation projects, fostering collaboration, and driving solutions from idea to commercialization. She thrives on helping teams bring innovative ideas to life and fostering an environment where experimentation and problem-solving lead to success.

Ensuring Flare Pilot Reliability: Preventing and Mitigating Fuel Supply Failures

Pilots are the heart of a flare. Without healthy pilots, a flare can easily become a vent. When a failure occurs in pilot fuel piping, it can significantly affect pilot performance and consequently flare performance. No one expects when installing a flare for the pilot fuel piping to fail, but it does happen. Insufficient tightening of threaded connections, flanges without double nuts or another mechanism to prevent loosening, flame impingement from adjacent flares, flame impingement from a damaged flare, improper piping support, and corrosion are all potential causes of pilot fuel piping failing. This paper will discuss steps that can be taken to mitigate the issue if it arises and preventative measures to lessen the probability of it occurring. The following assumptions are made:

- A flame front generator (FFG) is available and functional.

- The vent gas can’t be routed to another flare.

- The damaged flare will not be shut down for repair.

(Warning: Operation without pilots can result in the venting of waste gas and its consequences and may violate local regulations.)

Cold Weather Considerations for Flare Operations

Cold weather can create serious challenges for steam or water-assisted flares, leading to ice buildup that threatens both safety and performance. Ice blockages inside the flare can increase back pressure and risk overpressuring connected equipment, while external ice formations may compromise structural integrity and endanger personnel.

This guide outlines key equipment vulnerable to cold conditions and steps to mitigate risks. Cold weather, defined as any condition that causes water to freeze on or inside the flare system, becomes a concern when ice accumulates enough to impact operation or stability. For specific operational guidance, always refer to the manufacturer’s manual.

Techniques to Reduce Greenhouse Gas Emissions from Flares

Increased focus on greenhouse gas emissions is driving operators to explore ways to reduce those emissions. The flare is one area of interest for reduced emissions. This paper will explore various techniques that can be used to reduce greenhouse gas emissions from flares.

Bridget Taylor, Aftermarket Execution Manager

Meet Bridget Taylor, aftermarket execution manager at John Zink. Bridget joined John Zink in 2015 after earning her mechanical engineering degree, but her connection to the company runs much deeper. With a family legacy tied to John Zink—her grandfather worked at the company, and her father was a frequent customer—Bridget grew up familiar with the innovative work happening here. Now, she brings that personal connection full circle, leading a global team and helping shape the aftermarket portfolio with passion, collaboration, and a commitment to growth.

Emily Rohr, Application Engineering Manager

Meet Emily Rohr - As the application engineering manager for the vapor control team, Emily combines her passion for customers and engineering with a collaborative spirit, designing innovative solutions to meet emission control needs worldwide. With more than a decade of experience, Emily has grown her expertise and built lasting partnerships, driven by a love for teaching and a commitment to advancing the industry.

Ensuring Safe Ethylene Oxide Flaring: Proven Strategies from John Zink Experts

Ethylene oxide (EO) is an important chemical with a variety of uses as a chemical intermediate and as a sterilant. Derivatives of ethylene oxide include ethylene glycol, amines, solvents, and surfactants. As a sterilant, it is used to sterilize medical devices, spices, and other food products. While its properties make it indispensable, they also demand stringent safety measures. We leverage our deep expertise in combustion and emission control to ensure EO flaring is both effective and safe.

Jonathan Buskirk, Flares Retrofits Applications Engineer

Meet Jonathan Buskirk, who started as a draftsman at John Zink and is now a flares retrofit applications engineer, solving unique customer challenges. Drawn to the company’s supportive culture and focus on self-actualization, Jonathan quickly realized John Zink was the perfect place to grow and explore a variety of skills. Today, he’s helping customers tackle flaring challenges, combining technical expertise with commercial strategy. Jonathan’s journey highlights not only his passion for engineering but also the innovative and empowering environment that makes John Zink stand out.

Ronnie Springer, Manufacturing Manager

Meet Ronnie Springer, who joined John Zink in 2008, starting as a skilled machinist and developing into his current role as manufacturing manager. Passionate about empowering his team, Ronnie focuses on removing obstacles and fostering individual growth. Aligned with John Zink’s values, he thrives in the business’ culture of innovation and collaboration, leveraging the KES network to drive success.

Christian Tello, LATAM Business Development for Aftermarket

Meet Christian Tello, who joined John Zink in 2011 as a material coordinator and now leads LATAM business development for aftermarket. Throughout his career, Christian has embraced opportunities to grow, deepen his expertise, and strengthen customer relationships. Proud to contribute to John Zink’s legacy, he values the team’s supportive culture and encourages others to embrace challenges as opportunities for growth.

Bryan Stacy, Regional Account Specialist

Meet Bryan Stacy, regional account specialist and a valued member of the John Zink team since 2021. Bryan's journey here began with a recommendation from a friend, and he quickly connected with our guiding principles. In his role with the boiler burner aftermarket team, he thrives on the variety and challenge each day brings, collaborating closely with customers and colleagues alike. Bryan’s experience reflects the supportive, growth-focused culture he’s found at John Zink.

3 Proven Ways to Optimize Your Flare Systems and Reduce Emissions: Advanced Insights for Refinery Operators

Refineries rely on flares to safely burn waste gases, but these systems can also be significant sources of greenhouse gas (GHG) emissions. With tighter regulations and increasing sustainability goals, optimizing flare systems is essential. This article outlines three proven methods to reduce emissions and enhance flare efficiency, sharing advanced insights from John Zink’s decades of experience.

Matthew Vuong, Technical Service Advisor

Meet Matthew Vuong, a technical service advisor at John Zink who began his journey as an intern in 2015. Over the years, he has taken on various roles, continually expanding his expertise and passion for customer service. Known for his hands-on approach, Matthew ensures our vapor control and biogas equipment operates smoothly in the field. Let’s explore his career journey, favorite traditions, and what drives him to excel at John Zink.

Bill Lee, Strategic Account Representative

Meet Bill Lee, a strategic account representative at John Zink. Since joining in 2013, Bill has embraced a variety of roles, from the machine shop to sales, driven by his passion for learning and growth. In this spotlight, Bill shares his career journey, advice for new employees, and what excites him about the future at John Zink.

Hydrogen Firing in Tangentially Fired Boilers: The Future of Cleaner Combustion

As industries worldwide look for sustainable energy solutions, Hydrogen (H2) is emerging as a promising alternative to traditional fossil fuels. At John Zink, we’re leading the charge in innovating combustion technologies that meet the evolving needs of our clients. One area of focus is converting tangentially fired boilers from natural gas to hydrogen. This process offers exciting possibilities but comes with its own set of challenges.

Emergency Flare System Replacement Gets Plant Back Online In Record Time

As a long-standing customer of John Zink, Qatar Petrochemical Company (QAPCO) reached out to our team during an unexpected emergency. John Zink promptly assembled a team to address the issue and deliver an effective solution. QAPCO required a partner capable of meeting an extremely tight deadline. Within three days of the initial call, John Zink had traveled to QAPCO, met with their leadership team, and committed to providing a 90-meter tall, combined HC and acid flare system within just 32 days—a project that typically takes several months to complete.

Innovative Steam Flare Technology Significantly Improves Samsung Total Plant Flaring Operations

Samsung Total Petrochemicals Co., Ltd. replaced a steam-assisted flare tip at their main olefin plant in Daesan, Korea, with the STEAMIZER® XP™ technology from John Zink to increase smokeless capacity, enhance steam efficiency, improve flame stability, and reduce noise pollution. The results were impressive: smokeless capacity increased by approximately 195%, from 40,000 kg/hr to 117,800 kg/hr, using the same steam supply rate, and the flare became quieter and more stable. This success led Samsung Total to order another STEAMIZER XP-60 for the same facility.

Understanding Vapor Recovery Units (VRUs) and How They Work

Vapor recovery Units (VRUs) play a crucial role in the oil and gas industry by helping to capture and reclaim vapors that would otherwise be released into the atmosphere.

Reducing NOx Emissions and Retrofit Costs on Tangentially Fired Boilers

We assisted a major oil refinery in reducing NOx emissions on three 550,000 lb/hr tangentially fired boilers while considering retrofit cost, timeline, and equipment compatibility. The retrofit successfully achieved target emissions, received an award for exceptional performance, and showcased our expertise in optimizing industrial combustion systems.

A Comprehensive Guide to John Zink’s VCU Startup Process

When it comes to ensuring efficient and compliant vapor combustion, John Zink’s Vapor Combustion Units (VCUs) are widely recognized for their reliability and effectiveness. A crucial part of implementing a VCU is the startup process, which involves a series of steps and checks to ensure the system operates as designed and meets regulatory requirements. Below is a detailed overview of our VCU startup process.

What is a vapor combustion unit (VCU) and how does it work?

Vapor combustion systems, or Vapor Combustion Units (VCUs), are essential tools in gasoline, crude oil, ethanol, diesel, and other hydrocarbon and petrochemical applications, designed to safely and efficiently manage volatile gases and vapors.

Choosing Between Vapor Combustion Units (VCUs) and Vapor Recovery Units (VRUs): Making the Right Decision for Your Operation

When it comes to managing emissions of volatile hydrocarbon vapors, the choice between Vapor Combustion Units (VCUs) and Vapor Recovery Units (VRUs) is a critical decision. We will explore key considerations to help you determine which system is the right fit for your specific operation.

Kayla Chally, Engineering Solutions Advisor

Meet Kayla Chally, an engineering solutions advisor at John Zink. Kayla’s journey with John Zink began as an intern in 2016, and her passion for the company’s culture led her to a full-time position in 2017. In this spotlight, Kayla shares insights into her role, her professional development, and her contributions to John Zink’s innovative environment. Get to know more about Kayla, her achievements, and her beloved pups, Goose and Rooster.

Heat Recovery: Reducing Emissions and Improving Efficiency in Thermal Oxidizers

Thermal oxidizers are critical components in controlling emissions and maintaining environmental compliance in various industries. However, beyond their primary role in abating volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other waste gases, there’s a growing interest in enhancing their efficiency through heat recovery.

Adapting to New EPA Vapor Emission Regulations with John Zink’s Expertise

As industries continue to evolve, regulatory landscapes shift to ensure safety and environmental sustainability. The recent updates to the EPA’s NESHAP Subpart R, BBBBBB, and NSPS Subpart XXa represent significant changes for facilities handling bulk gasoline terminals and vapor control equipment. Understanding and navigating these updates can be challenging, but with John Zink’s expertise and innovative solutions, compliance becomes not just achievable but an opportunity for operational improvement.

Ben Bolin, Applications Engineer

Meet Ben Bolin, who started as a process engineering intern with John Zink in 2020 and joined full time in 2021 after earning his bachelor’s in mechanical engineering. Drawn by Koch and John Zink’s culture and growth opportunities, Ben is a new equipment applications engineer for the vapor control equipment product line. He handles design work, technical customer interactions, and project support. Ben enjoys seeing projects grow from ideas to operational systems and values the business’ encouragement of creative problem-solving and professional development.

Rebecca Hiatt, Flares Project Engineer

Meet Rebecca Hiatt, who joined John Zink in 2022 after graduating from OSU Tulsa. Drawn by John Zink’s culture and the role’s responsibilities, Rebecca found a great fit as a project engineer focused on process flares.

Meeting USCG Standards with John Zink’s Portable Marine Vapor Control Equipment

In the highly regulated maritime industry, meeting stringent safety and environmental standards is crucial for operations. Recently, a customer in the Gulf Coast area faced a significant challenge: they needed portable marine vapor control equipment that met U.S. Coast Guard (USCG) requirements. With no existing infrastructure in place for vapor control, they turned to John Zink for a reliable and efficient rental solution.

Adapting to Hydrogen: The Role of Radiant Wall Burners

The future of energy is undergoing a significant transformation, with hydrogen emerging as a promising, eco-friendly fuel source. The growing global demand for hydrogen is driven by its ability to generate water as its only byproduct during combustion, with minimal carbon dioxide emissions, depending on its production method. However, integrating hydrogen into various applications presents unique challenges, particularly when it comes to combustion systems. In this article, we explore how radiant wall burner technology is addressing the issues associated with introducing hydrogen fuels into combustion processes.

Raegan Peters, Applications Engineer

Meet Raegan Peters, an applications engineer specializing in thermal oxidizers. Starting as an intern in 2018, Raegan has grown into a full-time engineer who embodies our business’ values. Her collaborative spirit and commitment to excellence help customers navigate complex projects and find tailored solutions. Raegan’s journey highlights the growth opportunities and supportive culture at John Zink, where she contributes to our legacy by embracing innovation and principled entrepreneurship.

Understanding the Impact of Emerging HON Regulations on Thermal Oxidizer Design

The landscape of environmental regulations is constantly evolving, and staying ahead of these changes is crucial for industries dealing with hazardous emissions. A key focus of recent regulatory changes is the Hazardous Organic National Emission Standards for Hazardous Air Pollutants (HON), which impacts more than 200 facilities and targets substances affecting the Synthetic Organic Chemical Manufacturing Industry (SCOMI). One of the critical challenges in these regulations is predicting emission rates of dioxins and furans (CDD/CDF).

Hai Lai, Head of Technology, Vapor

Meet Hai Lai, Head of Technology – Vapor at John Zink. Hai started as an intern in 2013, seeking industrial experience before deciding to stay due to the excellent equipment, company culture, and friendships. Over the years, he transitioned from project management to process engineering, eventually becoming Head of Technology for the vapor control team. His journey at John Zink has been marked by continuous learning, mentorship, and contributions to innovative projects like the NOxSTAR™ low NOx combustor technology.

Breann Loeber, Application Engineer

Meet Breann Loeber, whose journey at John Zink began during her sophomore year with the Koch All Access Program. This experience sparked her passion for combustion technology, leading her to join John Zink as an intern in 2021 and transition to a full-time role in 2022. In her role, Breann blends technical design with customer interaction, working closely with customers to design flare systems that meet their needs. She also leads Oklahoma State University (OSU) campus recruiting, coordinates flare school at Koch Engineered Solutions Institute (KESI), and assists with intern programming, all while contributing to John Zink’s legacy of innovation and environmental stewardship.

Converting Oil Fired, T-Fired Utility Furnaces to Fire Gas and Oil

John Zink executed a successful conversion for Puerto Rico Electric Power Authority (PREPA), transforming two 410 MWe tangentially fired boilers at the South Coast Generating Station. The conversion involved equipping unit #5 and #6 boilers with advanced gas burners, safety valves, and pressure-regulating skids. This allowed PREPA to flexibly switch between natural gas and fuel oil firing, achieving fuel cost reduction and adherence to regulations. The conversion preserved existing oil-firing capabilities and optimized boiler performance, resulting in substantial operational benefits for PREPA.

The Journey to Net Zero Carbon Emissions: Challenges and Opportunities of Firing Hydrogen in Fired Heating

As leaders and organizations strive to reduce carbon emissions, the use of hydrogen as a fuel source continues to surface as a compelling alternative. Process heating through hydrogen combustion isn’t necessarily novel. The refining and petrochemical industries have leveraged the heating content in byproducts (many of those rich in hydrogen) to maximize unit efficiency, reduce the consumption of purchased fuel, and eliminate the release of unburned hydrocarbons to the atmosphere. While the carbon free nature to hydrogen offers a seemingly simple path to carbon free emissions, transitioning to hydrogen presents several challenges that, if unmitigated, will negatively impact the viability of products and services critical to our daily lives.

Navigating Vapor Control: Choosing the Right Technology

The control of volatile organic compounds (VOCs) is of utmost importance. VOCs, if released into the atmosphere, can have detrimental effects on the environment, acting as precursors to ozone and smog formation. Consequently, regulations worldwide demand the capture or destruction of VOCs to mitigate their release. To meet these requirements, two primary technologies are employed: vapor recovery units (VRUs) and vapor combustion units (VCUs). In this article, we will assess these vapor control options and introduce a suitable technology where vapor combustion technology is chosen.

Ensuring Operational Continuity: Thermal Oxidizer Rental for Railcar Cleaning Facility

Operational interruptions can be a significant challenge, particularly for facilities that require high-efficiency equipment to meet stringent regulatory requirements. This was the situation faced by a railcar cleaning facility that experienced a shutdown due to issues with its existing thermal oxidizer. With a permit demanding a destruction efficiency of 99.99%, finding a quick and effective solution was imperative.

How Burner Tiles Impact Combustion Efficiency and Emissions

In industrial processes and combustion systems, there’s a hidden hero that often goes unnoticed: the burner tile. It’s a common misconception that this essential component is merely a piece of refractory or firebrick. In reality, the burner tile is the “heart” of the burner, and its proper design, installation, and maintenance are critical for efficient burner performance. This article delves deep into the realm of burner tiles, shedding light on their crucial role in process burners and discussing the six key principles (the 6 Ms) that apply to burner tile design.

Tips for Operating a Vapor Control System to Maximize Its Lifespan

Vapor control systems play a vital role in operations, ensuring the safe and efficient disposal of harmful vapors. To maintain the longevity and reliability of these systems, proper operation and regular maintenance are essential.

John Zink Awarded VPP Star of Excellence

John Zink is dedicated to workplace safety, setting standards that prioritize the health and wellbeing of its employees. This commitment has been recognized with the Star of Excellence from the Occupational Safety and Health Administration’s (OSHA) Voluntary Protection Programs (VPP), reflecting not just compliance with safety protocols but a deep-rooted culture of safety involving all employees.

Understanding Ethylene Furnace Heat Flux Correlations

Efficiency and safety are paramount in the operation of ethylene-cracking furnaces. These critical processes produce ethylene through thermal cracking of hydrocarbon feedstocks, such as ethane and propane. However, managing heat flux profiles in these furnaces is crucial to prevent issues like coking, tube overheating, and equipment damage. In this blog post, we will explore the significance of heat flux correlations and how they can be applied to various ethylene furnace configurations.

Delivering the SOLEX™ Burner Combustion System and Lowering Emissions

John Zink successfully delivered the SOLEX burner combustion system, achieving less than 5 ppm NOx emissions and nearly zero CO emissions across a broad range of operating conditions. The SOLEX™ combustion system is John Zink's next-generation NOx technology industrial burner for process heaters in general refining service, designed with two combustion zones to achieve single-digit NOx emissions without traditional post-combustion treatment methods, such as selective catalytic reduction (SCR).

Duct Burner Solutions

Download

Tail Gas Thermal Oxidizer

Download

Proven Solutions for the Biogas Industry

Download

Process Heater MACT Compliance Solutions

Download

Carbon Adsorption Vapor Recovery Systems

Download

SOLEX™ Burner

Download

WALFIRE™ Radiant Wall Burner

Download

Air-Assisted Flares

Download

CFD Modeling Capabilities for Fired Heaters

Download

Preventative Maintenance

Download

Utility Solutions

Download

Equipment Rentals

Download

Turnkey Services

Download

Sulfur Recovery Combustion Solutions

Download

COOLstar® Burner

Download

LPMW™ Radiant Wall Burner

Download

DEEPstar™ Burner

Download

ECOjet® Edge Ultra-Low NOx Burner

Download

Rapid Mix Burner (RMB™)

Download

QLN® Burner

Download

Variflame™

Download

Dynaswirl-LN™

Download

Duct Burner

Download

ProLine In-Line Duct Burner

Download

Selective Catalytic Reduction (SCR) Systems

Download

LRGO™ Multi-Point Ground Flare

Download

Steamizer® XP™ Steam-Assisted Flare

Download

Fin Plate Burner for Enclosed Ground Flares

Download

LHTS™ Air-Assisted Flare

Download

SMART™ Air-Assisted Flare

Download

Demountable Flare Structures

Download

Vapor Recovery Units (VRUs)

Download

Crude Oil Vapor Recovery System

Download

Vapor Combustion Units (VCUs)

Download

NOxSTAR™ Vapor Combustion System

Download

Vapor Vacuum Control System (VAVACS)

Download

Marine Vapor Emission Control Systems

Download

InSite

Download

Selective Non-Catalytic Reduction (SNCR)

Download

Tail Gas Incinerator

Download

TriLo™ Technology

Download

Combustion Solutions for the Biogas Industry

Download

Sulfur Recovery Solutions

Download

COOLstar®+ Burner

Download