Features

- Efficient Combustion: High combustion efficiency for significant fuel cost savings and reduced emissions.

- Emissions Control: Low NOx emissions (0.12 to 0.18 lbs/MM Btu) and CO emissions (0.30 lbs/MM Btu).

- High Turndown Ratio: Ensures flexible operation and stable performance across different firing rates.

- Multi-fuel Capability: Processes various biomass fuels with heating values from ~6000 to 9000 Btu/lb and moisture content below 10%.

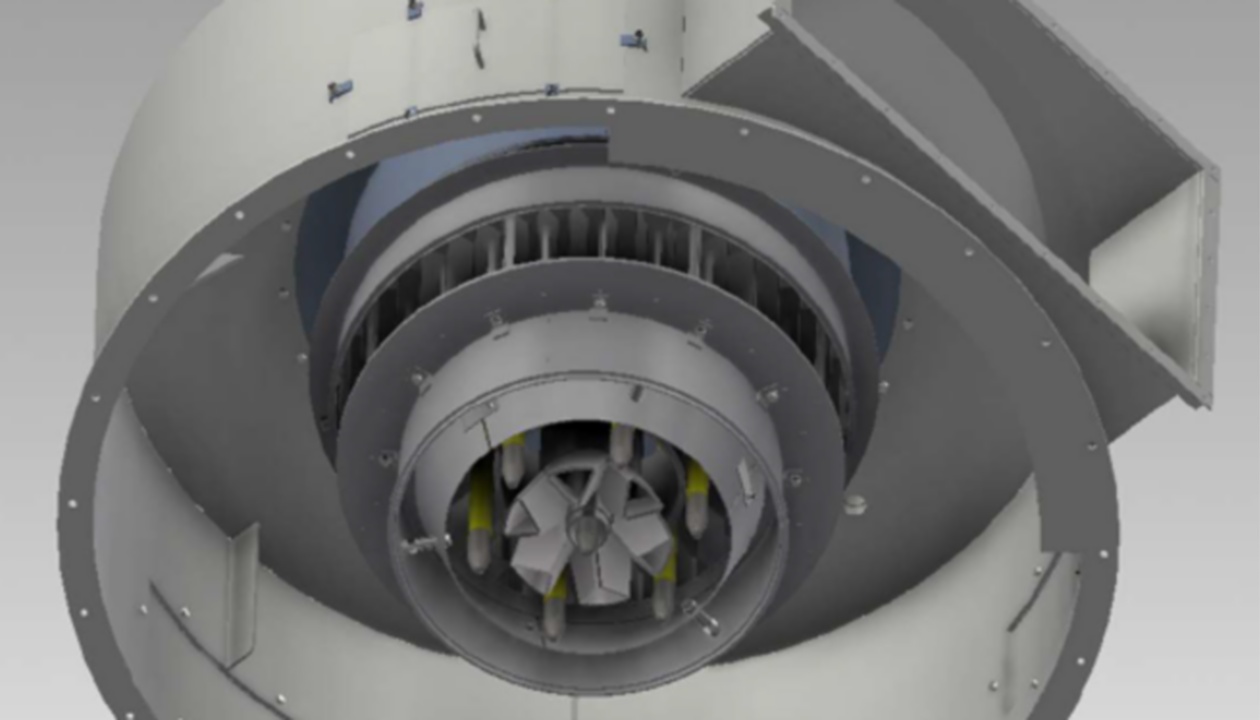

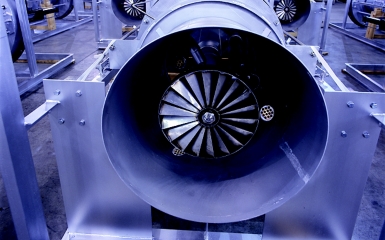

- Advanced Burner Design: Incorporates Coen Scroll Burner technology and John Zink Solid Fuel Nozzle for uniform fuel entry and efficient mixing.

- Ignition and Flame Scanning: Supported by a secondary fuel source and advanced flame scanners for stable operation.

- Turnkey Solutions: Comprehensive offerings include boilers, air heaters, burners, and complete control systems.