Features

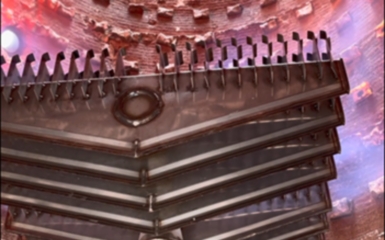

- Superior Combustion Efficiency: Advanced steam injection technology for cleaner combustion.

- Smokeless Operation: Effective mixing of steam and waste gases ensures minimal smoke.

- Reduced Emissions: Lowers the formation of harmful pollutants, enhancing environmental compliance.

- Durable Construction: Robust design for long-term reliability and reduced maintenance.

- Staged Steam Capable: Allows addition of staged steam technology to reduce steam consumption at turndown.

- Cooling Steam Reduction (CSR) Capable: Allows addition of CSR technology to reduce steam consumption during purge conditions.