Features

- High Efficiency: Achieves up to 95% NOx reduction.

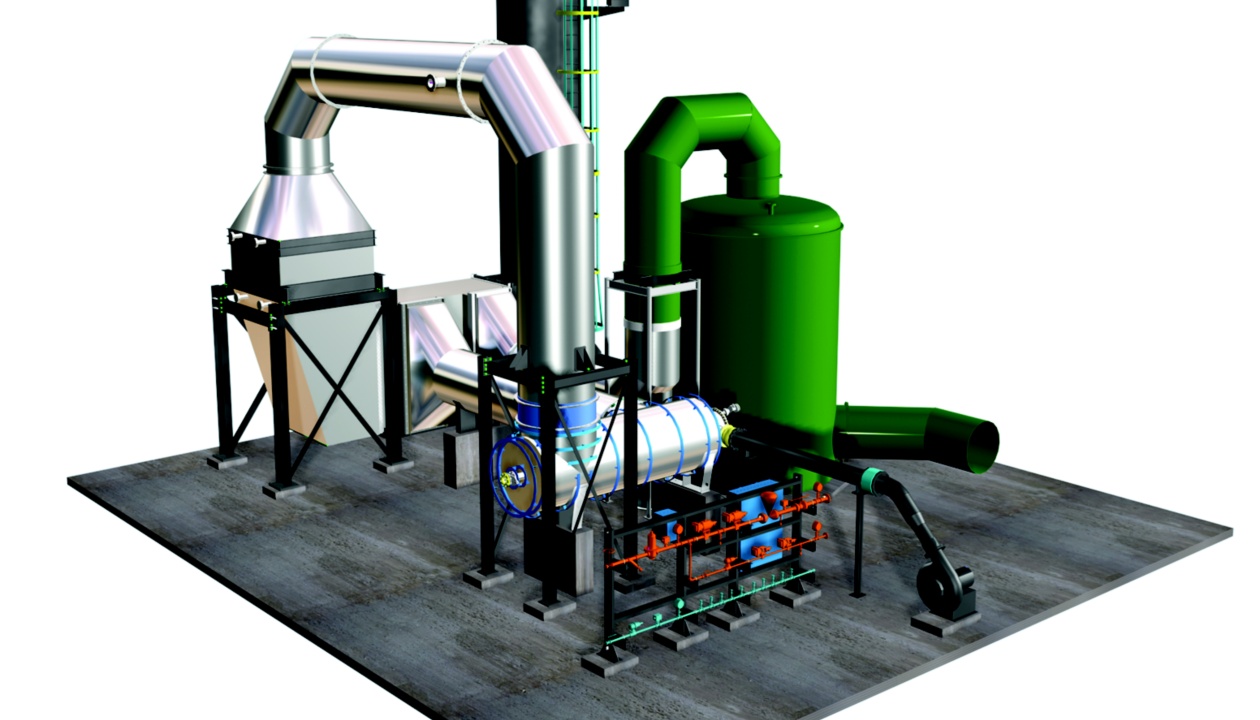

- Customizable Design: Tailored to meet specific process requirements and emission targets.

- Durable Catalysts: Long-lasting catalysts that ensure consistent performance over time.

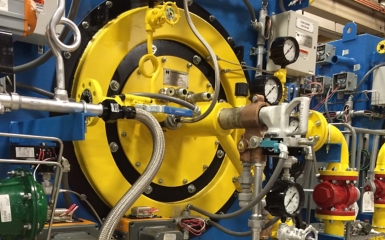

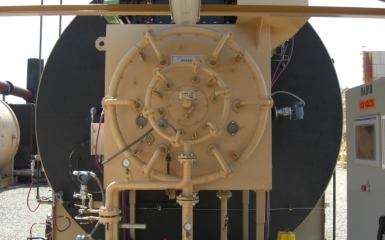

- Automated Control Systems: Advanced control systems for precise operation and monitoring

- Versatile Applications: Suitable for a wide range of industrial applications, including power plants, refineries, and chemical plants.