Features

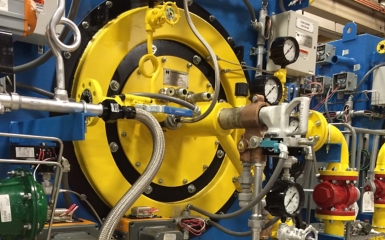

- Advanced Air/Fuel Premixing & Staging: Significantly reduces NOx emissions.

- Wide Firing Capacity Range: Up to 450 MMBTU/HR HHV.

- Multi-Fuel Compatibility: Suitable for natural gas, produced gas, syn gas, #2 fuel oil, and bitumen.

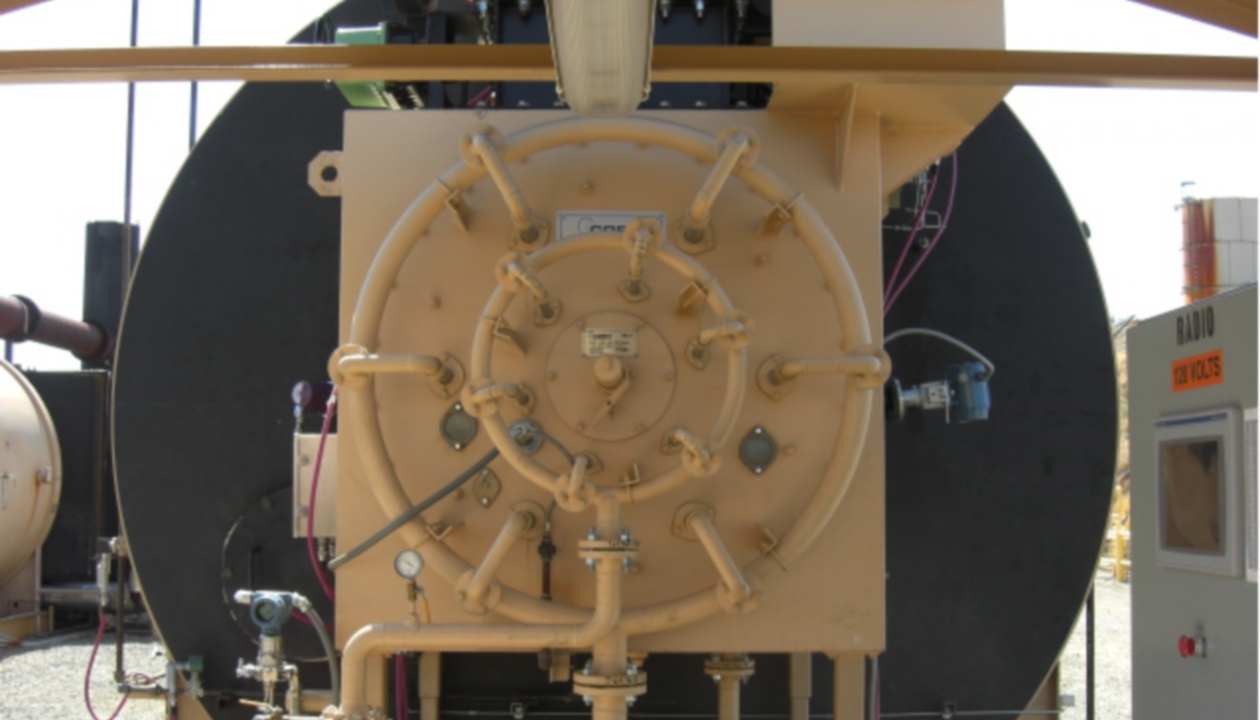

- Compact Design: Facilitates easy installation and maintenance.

- Robust Construction: Ensures long-term reliability and performance.