Features

- Ultra-Low NOx Emissions: Achieves NOx levels as low as 0.01 lbs/MMBtu.

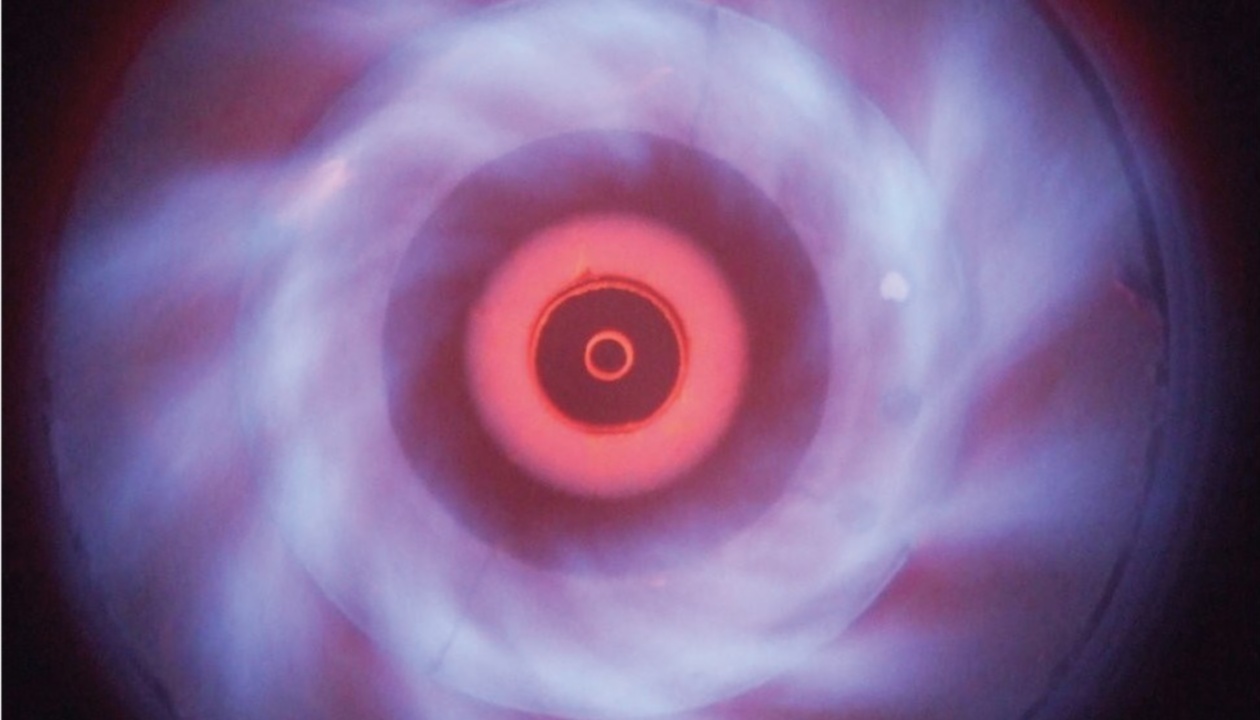

- Advanced Mixing Technology: Rapidly mixes air and fuel gas to minimize NOx formation.

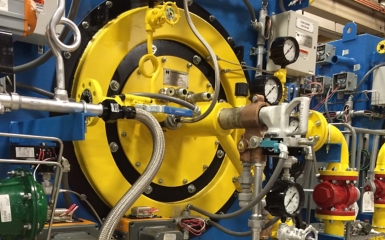

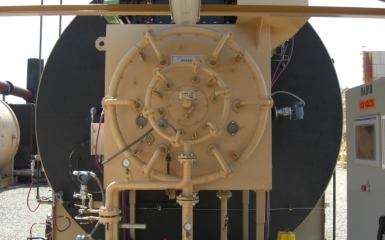

- No Moving Parts: Ensures high reliability and reduced maintenance.

- Compact Flame: Eliminates refractory impingement and reduces oxidizer dimensions.

- TruFire UltraFlex Pilot: Provides reliable startup and complete system heat-up and curing.

- Heat Inputs: Capable of handling up to 300 MMBtu/hr (90 MW) per burner.

- Versatile Fuel Compatibility: Fires natural gas, hydrocarbon fuels, and light oil as backup.