Overview

The Pinnacle of Burner Technology

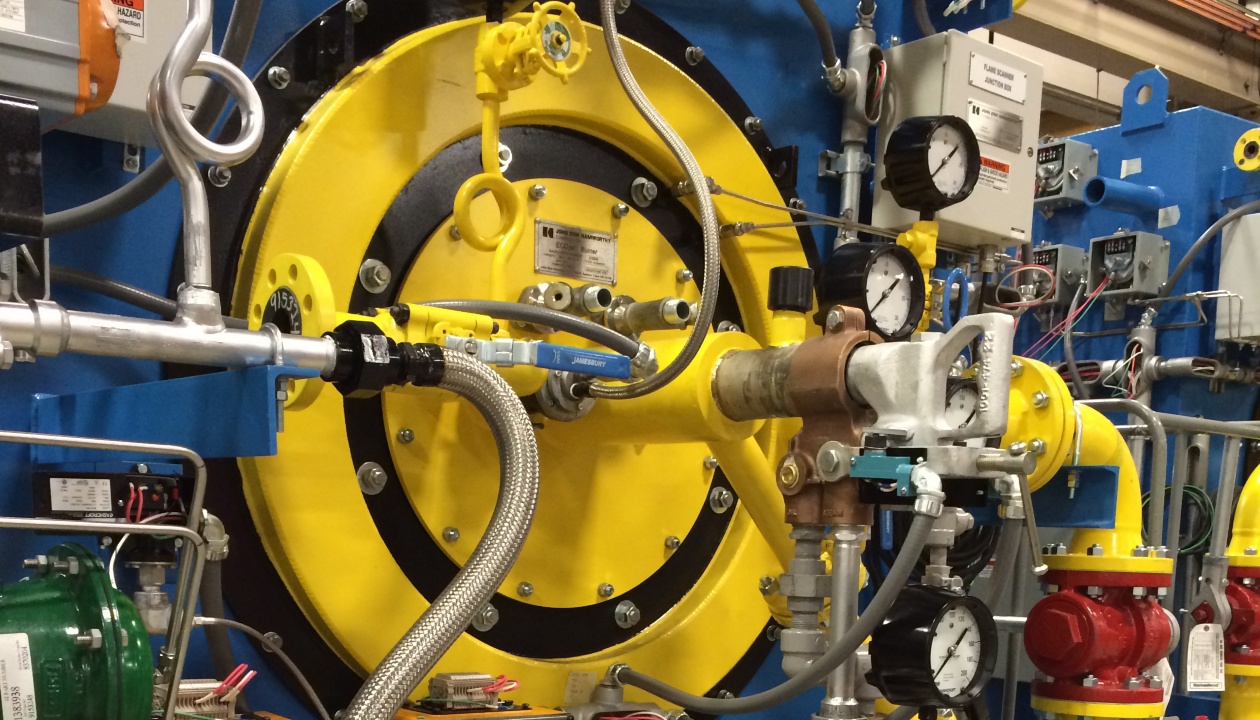

The ECOjet® Edge burner represents the pinnacle of burner technology, designed to achieve ultra-low NOx emissions with a variety of fuels. Building on the success of the original ECOjet burner, the Edge model incorporates advanced staged fuel injection and a versatile platform to meet diverse customer requirements.

Ideal for package, industrial, and utility boiler applications, the ECOjet® Edge features a long, narrow flame that ensures optimal performance and emission control. The burner’s innovative design leverages staged spuds outside the burner barrel, providing precise fuel-air mixing and enhanced combustion efficiency. This technology allows the ECOjet® Edge to achieve NOx levels below those of conventional burners, often eliminating the need for additional selective catalytic reduction (SCR) equipment.

With a self-cleaning high energy spark ignition system, the ECOjet® Edge ensures dependable startup and continuous operation, providing extremely stable flames with up to a 20:1 turndown for furnace warm-up and hot standby. Capable of firing various gaseous fuels, such as natural gas, propane, refinery gas, landfill gas, and off-gases, the ECOjet® Edge also excels with liquid fuels, including light gas oil, heavy fuel oil, and ultra-heavy fuels like pitch and bitumen.

The burner achieves NOx levels of less than 9 ppm with flue gas recirculation (FGR) and CO levels below 50 ppm, making it an environmentally friendly option for modern industrial needs. Additionally, its fast burner ramp rates and easy retrofitting capabilities ensure seamless integration into existing plants.