As leaders and organizations strive to reduce carbon emissions, the use of hydrogen as a fuel source continues to surface as a compelling alternative. Process heating through hydrogen combustion isn’t necessarily novel. The refining and petrochemical industries have leveraged the heating content in byproducts (many of those rich in hydrogen) to maximize unit efficiency, reduce the consumption of purchased fuel, and eliminate the release of unburned hydrocarbons to the atmosphere. While the carbon free nature to hydrogen offers a seemingly simple path to carbon free emissions, transitioning to hydrogen presents several challenges that, if unmitigated, will negatively impact the viability of products and services critical to our daily lives.

Understanding the Basics

Fired heating has been an effective and popular method for providing the necessary heat to drive chemical reactions in large industrial processes. Refining, reforming, and cracking processes have traditionally relied on readily available sources of energy (e.g. natural gas). Although fossil fuels have been a low-cost and efficient source of energy needed for oil refinement and distillation, the carbon contained in these fuels results in undesirable emissions that have long-term environmental impacts. However, hydrogen combustion mitigates the CO2 formation as a product of combustion, making it an attractive option for reducing greenhouse gas emissions.

Technical Challenges

Combustion Characteristics

Although the mechanics of hydrogen firing are similar to those of most other hydrocarbon fuels, burner performance is significantly different when firing hydrogen. Hydrogen combustion has a considerably higher adiabatic flame temperature, wider flammability limits, and faster rate of reaction. These properties will affect heat transfer rates, the overall efficiency of the process heater, and ultimately how furnaces should be operated. Furthermore, these characteristics can wreak havoc in fired heating equipment (e.g. premix burners) that may not be designed for it.

Burner Reliability

The high flame temperature, broad flammability limits, and flame speed of hydrogen can lead to increased wear and tear on the materials used in fired heating equipment. Overall equipment designs that perform well with natural gas might degrade at an accelerated rate when dealing with hydrogen combustion. This necessitates the development of more robust burner design strategies, alongside upgraded materials of construction, to reduce reliability concerns and achieve desired run lengths.

Safety Concerns

Hydrogen has a broader flammability range compared to natural gas, increasing the risk of ignition and explosions during start-up conditions. Implementing well-founded safety protocols and designing fail-safe systems are crucial to mitigate these risks.

Opportunities for Innovation

Advantaged Burner Design:

The unique properties of hydrogen combustion provide an opportunity to innovate in burner design. John Zink’s advantaged burners and technologies are tailored to thrive in the specific field operating. With decades of experience with firing high contents of hydrogen, burner development has been focused to tackle two key issues:

- Equipment reliability: Consumables in a process burner are, in practical terms, inevitable. Therefore, advantaged burner designs are going to be those that significantly and effectively reduce dependency on consumables without reducing burner performance.

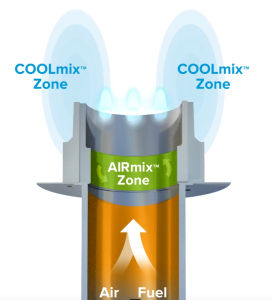

- Consistent operations: Next level of performance can be found when leveraging subject matter expertise to adjust combustion performance in real time to achieve the desired performance regardless of the change in fuel composition and combustion air temperature. The SOLEX burner can do just that. By leveraging two independent combustion zones, the stoichiometry in strategic parts of the burner can be adjusted effectively mitigate the risk of flashback while also optimizing NOx performance.

Figure 1 SOLEX burner combustion zones

- Safety Systems: The need for robust safety systems is fostering innovation in sensor technology and control systems. These advancements ensure that hydrogen can be used safely, reducing the risk of accidents and enhancing overall process reliability.

Economic Considerations

Transitioning to hydrogen requires significant capital investment. This includes retrofitting existing infrastructure, developing new equipment, and ensuring compliance with safety standards. While the long-term benefits of reduced carbon emissions are clear, the initial costs can be a deterrent for many applications. Governments and regulatory bodies can play a pivotal role by providing incentives and subsidies to offset these costs and encourage the adoption of hydrogen technology. Additionally, these investments in hydrogen infrastructure can enhance unit productivity and offer a payback on the decarbonization effort.